Host transformation

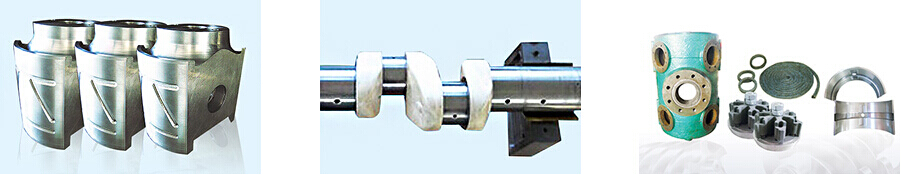

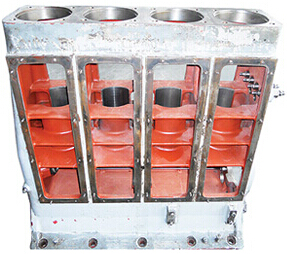

The difficulty of mapping and transformation is obviously more than the design. The difficulty gives us rare experience and makes us smart. At present, we have more than 40 kinds of compressors from different countries, and we have accumulated rich experience. The localization and transformation of imported compressor parts, we solved: ● Standard question, neither metric nor imperial, but a national standard, such as thread, no inspection, no measuring ●Material problems: such as aluminum alloy cross head, aluminum bearing bush ●Structural problems: If the cylinder liner is less than 2mm thick, it is difficult to process, hot or cold. |  |

| ● Strength problem: If the diameter of the connecting rod bolt is too thin, it is very different from the national regulations, and the bolt hole is enlarged, and it is worthless. ●Vibration problem: If the weight of the connecting rod or piston is not handled properly, different vibration results will be caused in horizontal, upright and angled compressors. | |